Researchers Develop New Continuous Transesterification Process for Biodiesel Production

“Researchers at Augsburg College and SarTec Corporation have developed and are commercializing a new continuous transesterification process for the production of biodiesel. The “Mcgyan Process”—so termed based on the names of the inventors (McNeff, Gyberg and Yan)—can use a wide variety of feedstocks, does not consume the catalyst, reduces the reaction time from hours to seconds, and uses no water or dangerous chemicals.

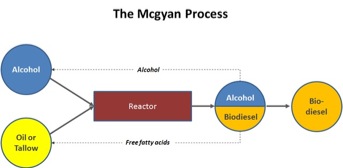

An alcohol and a lipid (vegetable oil or tallow) are combined by high pressure pumps into a lipid stream that is passed through a continuous fixed-bed reactor filled with a sulfated metal oxide catalyst at elevated temperature and pressure. The reactor performs transesterification and esterification reactions simultaneously.

The output contains excess alcohol and biodiesel fuel. The fuel is then distilled to recover the excess alcohol and other coproducts, and the biodiesel is polished to remove residual free fatty acids, which can be recovered and put back into the input side of the system.

Benefits of the Mcgyan process, according to the inventors, are:

• Flexible feedstock; animal or plant sources of lipids can be used. Current waste products can be turned into fuel.

• No use of strong acids or bases in the process.

• Fast reaction times (seconds).

• Cheap feedstocks such as waste grease and animal tallow as well as a variety of plant oils can be converted to biodiesel.

• The metal oxide based catalyst is a contained in a fixed bed reactor thereby eliminating the current need to continuously add catalyst to the reaction mixture thereby reducing the amount of waste produced.

• Unwanted side reactions with free fatty acids producing soaps are eliminated, thereby reducing the amount of waste that must be disposed of properly.

• Insensitive to free fatty acid and water content of the feedstocks.

• The catalyst does not poison over time.

A patent is now pending on the Mcgyan process. Ever Cat Fuels Corporation is a new company currently producing 50,000 gallons of biodiesel per year using the Mcgyan process. Its production capacity will increase to 3 million gallons per year when a new plant begins operation in Isanti (MN) later this year. Then, Ever Cat Fuels hopes to sell the technology and equipment globally.”